Informationen über PET Recycling

|

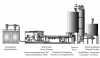

The new generation of our PET Recycling lines showsSIKOPLAST`s years of experience with PET recycling. Our first PET recycling line has started production in 1975., very low viscosity loss- / IV-degradation - depending on the processed material increase of viscosity possible, careful material processing, energy saving Inline-Cristallisation of the regranulate, granulate suitable for high quality products, granulate suitable for „Bottle to Bottle“-processing The feedstock will be stored in a silo, to guarantee a continuous feeding of the following dryer unit.At the beginning the flakes will be warmed up, crystallized and dried.In the next step these flakes will be dried completely in the second dryer stage, before feeding it into the extruder.A vacuum will be requested to keep the viscosity or even to increase it. The extruder feeding section as well as the degassing zone of the extruder are working under vacuum conditions, with the purpose to omit the volatile components, especially water out of the melt.Only the extraction of the water allows an increase of the viscosity (IV).Since the feeding section of the extruder is also working under high vacuum conditions, it allows an elimination of the water, out of the molecular connected water from the PET material, before a degradation of the material even could start.A fully-automatic working underwater pelletizing system guarantees equally sized pellets.A special design of our underwater pelletizers UWG allows an energy saving inline cristallisation of the pellets, since the remaining heat of the granulate will be used.

|